Technological Edge

We have independently developed cutting-edge solid-liquid separation technologies and continuously innovated processes, boasting high separation efficiency and excellent results, and can handle complex working conditions.

Customized Solutions

With rich experience, we understand clients' unique needs. Our pros communicate closely, offer customized solutions for production processes, streamline operations, cut waste, and maximize benefits.

Exceptional Quality

We follow ISO and other int'l standards for quality control. Our equipment, made with advanced tech and quality parts, is reliable, stable, runs long - hours, cuts replacements and maintenance costs, saving customers money.

Global Reach

We have established a global service system. No matter where customers are in the world, they can quickly obtain professional and timely after-sales services, which strongly guarantees the stable operation of the equipment.

ABOUT US

Focus on Filtration, Deliver Purity

Technological Innovation

Quality Assurance

We are a company specializing in the research, development, manufacturing, and sales of filter presses, dedicated to providing efficient and eco-friendly solid-liquid separation solutions.Our products are widely used in the environmental protection, chemical, mining, and food industries.With advanced technology and precision filtration systems, our equipment excels in filtration accuracy, automation, and energy efficiency.

- Diverse and Professional Capabilities

- Wide Application and High Recognition

- Green and Customized Services

Regular Filter Press

Alternating plates and frames with filter cloth form separate chambers. Features simple structure and flexible assembly, ideal for small-batch intermittent filtration. Easy cloth replacement and low maintenance with high operational flexibility.

High-Pressure Diaphragm Filter Press

Elastic diaphragms in plates enable secondary cake compression, reducing moisture below 15%. Energy-efficient with outstanding dewatering performance, meeting precision process requirements.

Automatic Filter Press

Fully automated operation with PLC control for plate shifting, discharge and cleaning. Significantly reduces labor costs while improving processing speed, ideal for high-standard production.

Filtering with precision, delivering purity

We specialize in the cutting - edge technologies of solid - liquid separation, integrating the concepts of high - efficiency, energy - saving, and environmental - friendliness. We tailor - make outstanding solutions for fields such as lithium - battery new energy, sand and gravel aggregates, municipal engineering, chemical industry, printing and dyeing industry, food and medicine, and tailings treatment.

Sand, Tailings & Metallurgy

Tailings Treatment: Used for dewatering sand and aggregate tailings, reducing environmental pressure on tailings storage facilities.Metallurgical Slag Treatment: Processes solid waste from metallurgical operations, achieving slag-water separation and resource recovery.

Municipal Sludge Treatment

Treat chemical wastewater and printing and dyeing wastewater to remove solid particles and harmful substances from the wastewater.

Wastewater treatment

Treat chemical wastewater and printing and dyeing wastewater to remove solid particles and harmful substances from the wastewater.

Blog

Filter Press for Food Waste Digestate: Smart Waste Solution

Filter Press for Foo

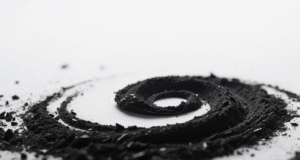

Filter Press for Carbon Black: Efficient Slurry Separation

Using a filter press